FOSSILIONTECH - The Sharp Singularity nano-ESI Emitters

Product Overview

Pulled capillaries form extremely sharp tips with small tip IDs, but they can be prone to clogging. Tapered emitters are more repeatable and less prone to clogging because they have a constant inner diameter, but achieving sharp tips is more difficult because it requires removing more material from very thin glass walls.

FossilIonTech's unique micro-machining process produces extremely sharp emitters (15º solid angle) with tight geometric tolerances and a constant ID.

'The Sharp Singularity' emitters combine repeatability as a result of their tight geometric tolerances and spray stability thanks to their very sharp tip.

Why sharper is better:

The minimum wetting contact angle an emitter can accommodate is limited by its angle. Sharper emitters can accommodate wider wetting angles.

The electrostatic fields tangent to the surface of the emitter keeps the meniscus centered and aiming straight by compensating for the effect of the surface tension, which pushes the liquid to climb backwards. Sharper emitters produce more stable sprays because the tangent component of the electrostatic field is stronger. Sharper emitters can accommodate a wider range of local electric fields (voltages), surface tensions and wetting contact angles.

Choosing the right ID and tip-OD:

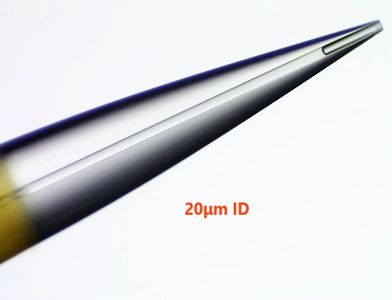

The size of the meniscus is defined by the OD at the tip. Smaller meniscus lead to lower evaporation rates, better ionization efficiencies, and better detection limits in proteomic workflows. They require lower voltages and delay the onset of discharges, leading to more stable sprays. On the other hand, small ID's are more prone to clogging, and age more rapidly. The ideal emitter diameter is the result of a balance: The largest possible ID and the smallest possible tip OD. The choice of the ID of the emitters is a trade-off decision, between performance and robustness.

Pulling vs sharpening:

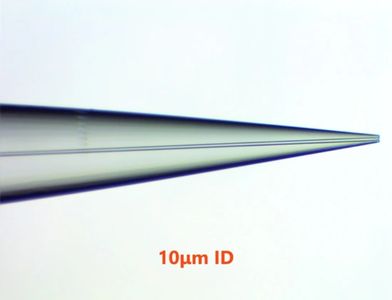

- Pulled capillaries form extremely small tip IDs, but they can be prone to clogging because the inner diameter decreases along the capillary length.

- Micro-machined capillaries can be more repeatable and robust because they can reach very tight geometric tolerances with a constant inner diameter, less prone to clogging. But achieving very sharp edges is more difficult because more material needs to be removed.

- FossilIonTech's unique micro-machining process produces very sharp emitters (7.5º semi-angle) with tight geometric tolerances and a constant ID. Thus combining the advantages of pulled and normal tapered emitters.

'The Sharp Singularity' emitters combine repeatability thanks to their tight geometric tolerances and spray stability thanks to their very sharp tip. All emitters are delivered with a Quality and Traceability control report, with microscopy photos to ensure you have all details about your spray. ID from 10 μm to 50 μm.

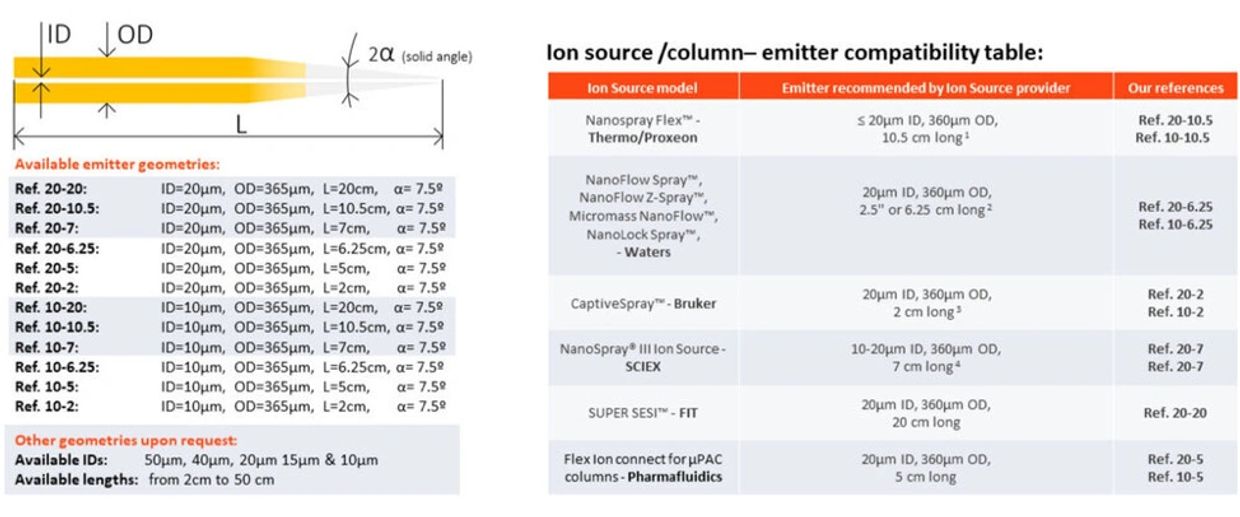

Identify the best emitter geometry for you:

We recommend specifying the right length for your application so that you do not need to cleave the emitter. The Sharp Singularity nano-ESI emitters are straight cut and polished at the back to ensure they sit properly in their fitting. For special requirements, please contact us to review.